Key information

- Date: Took place May 2024. Scheduled again 2026. Register your interest.

- Location: University of Hull

- Duration: 2-day Masterclass

- Specialist access to laboratory-scale composite manufacturing facilities, Fibre

Bragg grating and optical time domain reflectometer analysis equipment.

Pricing

- General participant rate: £1000 - Course materials and lunch included.

- Eligible Early Career Researchers: Free - In line with EPSRC funding policy, the cost is covered for UK-based academic researchers who meet the definition of an Early Career Researcher (Post Doctoral Research Assistants (PDRAs), early career academic staff within the first three years of their academic appointment, or PhD students within 12 months of completion who are exploring a future career in the ORE sector), and are part of our network. There will be no charge for eligible Early Career Researchers to attend a Masterclass, but they will be responsible for covering expenses such as travel and accommodation.

Included in your day

- Unparalleled access to the most up-to-date knowledge in a session created by academics at the forefront of ORE research and teaching

- Access to world-class facilities and hands-on demonstrations

- Electronic access to course material and presentations after the masterclass

- Networking opportunities

- Q&A session with Course Director(s)

- Morning, lunch and afternoon refreshments

- Electronic certificate of attendance

About the Masterclass

This 2-day Masterclass will explore the latest advancements in sensing systems and associated signal processing techniques to monitor the manufacture and operation of offshore renewable energy systems including turbine blades, and static and dynamic cables. Participants will gain a comprehensive understanding of a range of sensors, associated infrastructure and the signal processing techniques required to extract load data and detect defects. Particular emphasis will be placed on fibre optic sensors for wind and tidal blade structures and monitoring of both manufacturing processes and operational behaviour.

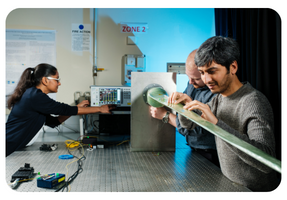

Participants will gain hands-on experience in applying fibre optic sensors to scaled structures and deriving load measurements. The Masterclass includes specialist access to laboratory-scale composite manufacturing facilities, Fibre Bragg grating and distributed fibre sensors with optical spectrum analysis and optical time domain reflectometer analysis equipment.

Upon completion, participants will understand the underlying principles of discrete and distributed fibre optic sensors and associated interrogation techniques as well as have valuable insight into the approaches, trade-offs and challenges of interrogating large arrays of fibre optic sensors using time and wavelength multiplexing methods.

Drawing on expertise from 10 UK universities, the Supergen ORE Hub is in a unique position to offer the opportunity to learn directly from the UK's foremost specialists in offshore renewable energy at world-leading facilities. To book your place on this Masterclass we encourage you to register early as places are limited. This Masterclass is scheduled to run a second time in Spring 2026.

| Topics covered |

|---|

| Introduction to sensing systems for offshore renewable energy structures |

| Structural Health Monitoring and Condition Monitoring systems |

| Fibre optic sensing for monitoring the manufacture of composite structures |

| Fibre optic sensors for load and defect monitoring in wind/tidal blades and cables |

| Demonstrations and facilities |

|---|

| Integration of fibre optic sensors into blade structures during composite manufacturing processes. |

| Scaled wind turbine blade |

| Laboratory scale composite manufacturing facilities |

| Fibre Bragg grating |

| Distributed fibre sensors with optical spectrum analysis |

| Optical time domain reflectometer analysis equipment |

| Hands on activities | |

|---|---|

| Scaled wind turbine blade | Sensor interrogation and multiplexing |

| Scaled wind turbine blade | Extracting load data from fibre optic sensors |

| Scaled wind turbine blade with introduced defect | Defect detection from fibre optic sensors |

| Wind turbine Simulation | Signal processing for Structural Health Monitoring |

Masterclass Directors

- Professor James Gilbert - Professor of Engineering, University of Hull

About the Masterclasses Series

World-class expertise

Funded by the EPRSC, the Supergen Offshore Renewable Energy (ORE) Hub offers research leadership to accelerate the development of wind, wave, and tidal energy. We are a collaboration of 10 UK Universities that are pioneering innovative ORE research. Drawing on this expertise, our Masterclass programme is a unique opportunity to learn directly from the country’s foremost specialists in offshore renewable energy.

Unique and specialist

Pivot your career by engaging with specialist ORE researchers and access cutting-edge facilities not found in standard commercial training. Study post-graduate content in highly specialised 1 or 2 day courses. Gain a unique advantage in your work by learning innovative solutions from researchers working at the forefront of ORE. This is a unique and limited opportunity to join the best UK-based specialists at world-leading testing sites.

Hands-on learning

Immerse yourself in a dynamic learning environment through a blend of lectures, live demonstrations, and engaging hands-on activities. Benefit from the knowledge and experience of industry-leading professionals.